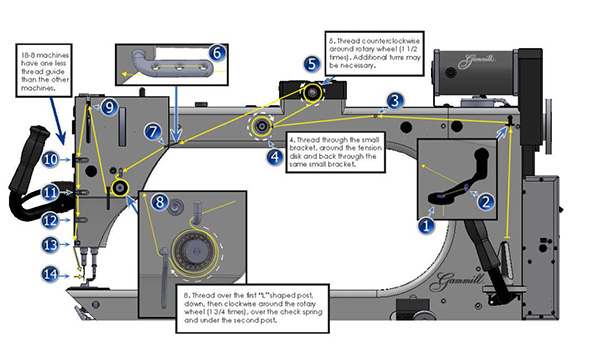

Threading the Machine

Changing Thread

It is not necessary to re-thread the machine each time you change thread. Simply cut the old thread before the first thread guide, leaving the machine threaded. Put the new spool or cone on the machine and tie the end to the old thread that is still in the machine.

Unthread just the needle and pull the old thread until the new thread appears. Cut off the old thread and thread the needle with the new thread. The tension should be checked each time a new thread is added.

Thread Guides and Posts

The purpose of these elements of the thread path is to position the thread for other elements such as the tension devices, needle and the take-up lever. Thread guides and posts may seem unimportant, but if one is omitted or improperly threaded you can have as poor stitch quality as you do if the tension is improperly set or the timing is off.